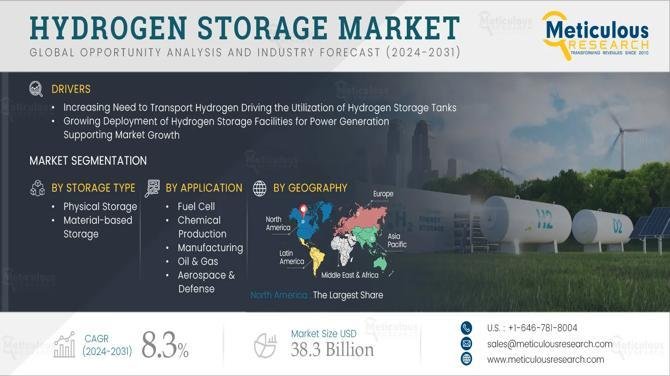

This most recent report from Meticulous Research® projects that the market for hydrogen storage will grow at a compound annual growth rate (CAGR) of 8.3% to reach $38.3 billion by 2031.

The growing usage of hydrogen storage tanks for transportation and the expanding use of hydrogen storage facilities as a source of energy for power generation are the main factors propelling this market's expansion. However, the market's expansion is constrained by the high capital expenditures of hydrogen storage facilities.

Material Compatibility: The Understated Barrier

At the heart of every hydrogen storage solution, whether it’s a high-pressure tank or a cryogenic vessel, lies the challenge of finding materials that can safely and reliably contain hydrogen. The problem? Hydrogen atoms are extremely small and mobile. They can seep into the tiniest crevices of many metals and polymers, causing those materials to degrade over time. Metals may lose flexibility or develop micro-cracks, while some plastics can swell, weaken, or become brittle after prolonged hydrogen exposure. The need for advanced alloys and special polymers ramps up storage costs and limits design choices, restricting large-scale deployment. Material compatibility is therefore a top concern and hinges on ongoing research into both new and improved materials.

Hydrogen Embrittlement: A Threat to Infrastructure Longevity

Infrastructure is directly at risk from "hydrogen embrittlement," one particular consequence of hydrogen's interaction with metals. A metal is more likely to fracture under stress when hydrogen molecules enter its structure. Storage tanks, pipelines, and valves may develop unseen cracks with continued use that could eventually cause leaks or catastrophic failure. As a result, hydrogen storage systems have a shorter lifespan, require more maintenance and inspections, and are more likely to experience unplanned downtime or safety concerns.

Why High-Pressure and Cryogenic Storage Dominate the Field

High-pressure gas tanks, which store hydrogen at 350–700 bar, and cryogenic tanks, which chill hydrogen to -253°C and transform it into a liquid, are currently the two most popular techniques for storing huge volumes of hydrogen. These techniques are preferred because they facilitate rapid vehicle fueling, allow for the storage of large amounts of hydrogen in manageable sizes, and integrate with current transportation infrastructures. Both promote the increasing need for hydrogen in fields like grid balancing for the integration of renewable energy sources and transportation, including fuel cell vehicles. Nevertheless, each has drawbacks, such as the high energy consumption for cooling or pressurization, the previously mentioned engineering difficulties, and the increased expense of advanced materials.

The Cost Equation: Why Cheaper Hydrogen Means Faster Growth

In comparison to traditional fuels, the cost of manufacturing hydrogen, particularly "green" hydrogen produced from renewable resources, is still high today. The price tag is further increased by the expenses of safety measures, storage equipment, and appropriate materials. The market for hydrogen energy storage may expand much more quickly if these expenses decline. More reasonably priced hydrogen would stimulate investment in reliable storage and transmission infrastructure, open up new markets, and promote the use of fuel cell vehicles. In summary, whether for industry, power generation, or automobiles, cost reductions are crucial to the widespread use of hydrogen storage systems.

Safety: The Non-Negotiable Consideration

Safety is crucial while working with hydrogen. Due to the small size of its molecules, the gas is highly combustible, colorless, odorless, and prone to leakage. Hydrogen fires are almost undetectable, and leaks can produce explosive atmospheres when combined with air. As a result, hydrogen storage systems need to include sensitive sensors, strict leak detection, adequate ventilation, and operator training. Establishing and upholding impeccable safety records is essential for gaining the trust of the public and regulatory approval. Strong standards and proactive risk management are essential since any accidents can damage trust and impede adoption.

Key Players:

The key players operating in the hydrogen storage market include L’Air Liquide S.A. (France), Chart Industries, Inc. (U.S.), Linde GmbH (Germany) (A subsidiary of Linde plc), Matheson Tri-Gas, Inc. (U.S.) (A subsidiary of Nippon Sanso Holdings Corporation), Hexagon Purus ASA (Norway), Luxfer Gas Cylinders (England) (A subsidiary of Luxfer Holdings PLC), Merck KGaA (Germany), Hanwha Corporation (South Korea), Eutectix LLC (U.S.), HBank Technologies Inc. (Taiwan), SPG Hydrogen Co., Ltd. (South Korea), FIBA Technologies, Inc. (U.S.), American Elements (U.S.), NPROXX B.V. (Netherlands), Steelhead Composites, Inc. (U.S.), CALVERA HYDROGEN, S.A. (Spain), and Pragma Industries (France).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5653

Contact Us:

Meticulous Research®

Email- sales@meticulousresearch.com

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research