CNC turning has transformed how industries produce high-quality components with minimal error. From aerospace to automotive, this technology is the backbone of advanced part production.

Choosing the right CNC turning company ensures consistent results, faster turnaround times, and superior quality control. With advanced CNC machines, manufacturers can create intricate and accurate components that meet exact specifications while reducing waste and labor costs.

Why Custom CNC Turning Services Are Essential

Every industry has unique needs, which is why custom CNC turning services are vital. Unlike standard solutions, customized services allow for tailored production based on material, design, and functional requirements.

When partnering with a specialized CNC turning company, you gain access to:

-

Tailored designs created to exact specifications

-

Flexibility in material choices, including metals and plastics

-

The ability to produce prototypes or large production runs efficiently

By leveraging custom CNC turning services, manufacturers can reduce lead times and achieve results that meet industry-specific standards without compromising quality.

Advantages of Aluminum CNC Turning Services

One of the most widely used materials in CNC turning is aluminum due to its lightweight, durability, and corrosion resistance. Companies specializing in aluminum CNC turning services provide components ideal for aerospace, electronics, and automotive sectors.

Key Benefits Include:

-

Lightweight strength: Perfect for high-performance applications

-

Excellent machinability: Allows for precise and clean finishes

-

Corrosion resistance: Ideal for harsh environments

A reputable CNC turning company with expertise in aluminum ensures each part maintains superior dimensional accuracy while meeting stringent performance requirements.

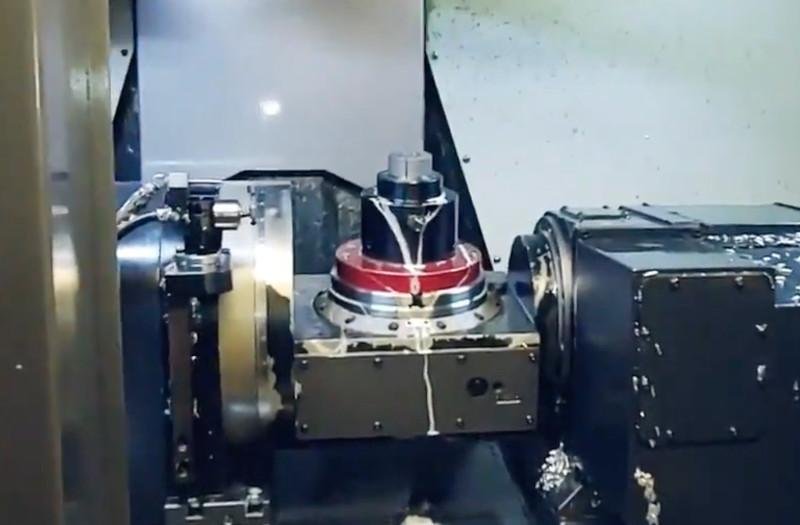

Precision with CNC Lathe Machining Services

CNC lathe machining services are integral to manufacturing precise cylindrical or round parts. This process involves rotating a workpiece while cutting tools remove material to form the desired shape.

Industries Benefiting from CNC Lathe Machining Services:

-

Automotive: Shafts, gears, and engine components

-

Aerospace: High-strength, lightweight precision parts

-

Electronics: Connectors and small precision fittings

Partnering with a skilled CNC turning company offering CNC lathe machining services ensures every part meets tolerance specifications, guaranteeing performance and reliability.

The Importance of Custom CNC Turned Parts

High-performance industries rely heavily on custom CNC turned parts that meet exact requirements. Whether it's a prototype or bulk production, these parts must be dimensionally accurate and consistent in quality.

Applications of Custom CNC Turned Parts:

-

Medical devices requiring ultra-precise components

-

Automotive fittings for safety and efficiency

-

Industrial machinery where durability is critical

By collaborating with a trusted CNC turning company, manufacturers can receive custom CNC turned parts that fit seamlessly into their products, improving performance and reducing downtime caused by part failures.

Why Choose a Reliable CNC Turning Company?

Selecting the right CNC turning company involves more than just equipment capability—it’s about expertise, quality assurance, and customer support. A professional company:

-

Uses cutting-edge CNC machines for maximum precision

-

Adheres to international quality standards

-

Offers end-to-end support, from prototyping to mass production

Zintilon, for instance, focuses on delivering custom CNC turning services backed by advanced technology and skilled machinists, ensuring each project meets the highest level of precision and consistency.

Custom CNC Turning Services for Diverse Industries

Different industries require varied approaches to machining. A versatile CNC turning company understands these demands and adapts its custom CNC turning services accordingly.

-

Aerospace: Lightweight aluminum components for high-altitude performance

-

Medical: Precision-machined parts that meet regulatory compliance

-

Automotive: High-strength steel parts for durability and safety

Such adaptability ensures businesses get the exact parts they need to maintain efficiency and product reliability.

How CNC Lathe Machining Services Improve Efficiency

Investing in CNC lathe machining services reduces human error while increasing production speed. Automation ensures round-the-clock manufacturing, resulting in faster delivery times and consistent output.

A well-equipped CNC turning company can handle complex geometries and large-scale projects without compromising on quality, making it a critical partner for modern manufacturing needs.

The Future of CNC Turning Technology

As technology evolves, CNC turning companies continue to adopt innovations like AI-driven machining and digital simulations. These advancements allow manufacturers to predict outcomes, optimize cutting paths, and minimize material waste.

By staying ahead with cutting-edge tools and custom CNC turned parts production techniques, businesses benefit from higher precision, reduced costs, and improved scalability.

Conclusion:

In today’s competitive market, collaborating with an experienced CNC turning company is essential for businesses that demand precision, speed, and flexibility. From custom CNC turning services to aluminum CNC turning services and CNC lathe machining services, skilled professionals ensure every part meets industry standards.

Whether you require prototypes or large-scale production of custom CNC turned parts, a trusted partner like Zintilon can streamline your manufacturing processes and deliver exceptional results.