Engineered automation is transforming how industries operate, offering smarter, more efficient solutions to boost productivity and precision. By integrating advanced technology, businesses are streamlining workflows, reducing human error, and setting the stage for long-term growth. But why does engineered automation matter so much, and how can it benefit your business? Let's explore its applications, advantages, and the exciting possibilities it brings.

What is Engineered Automation?

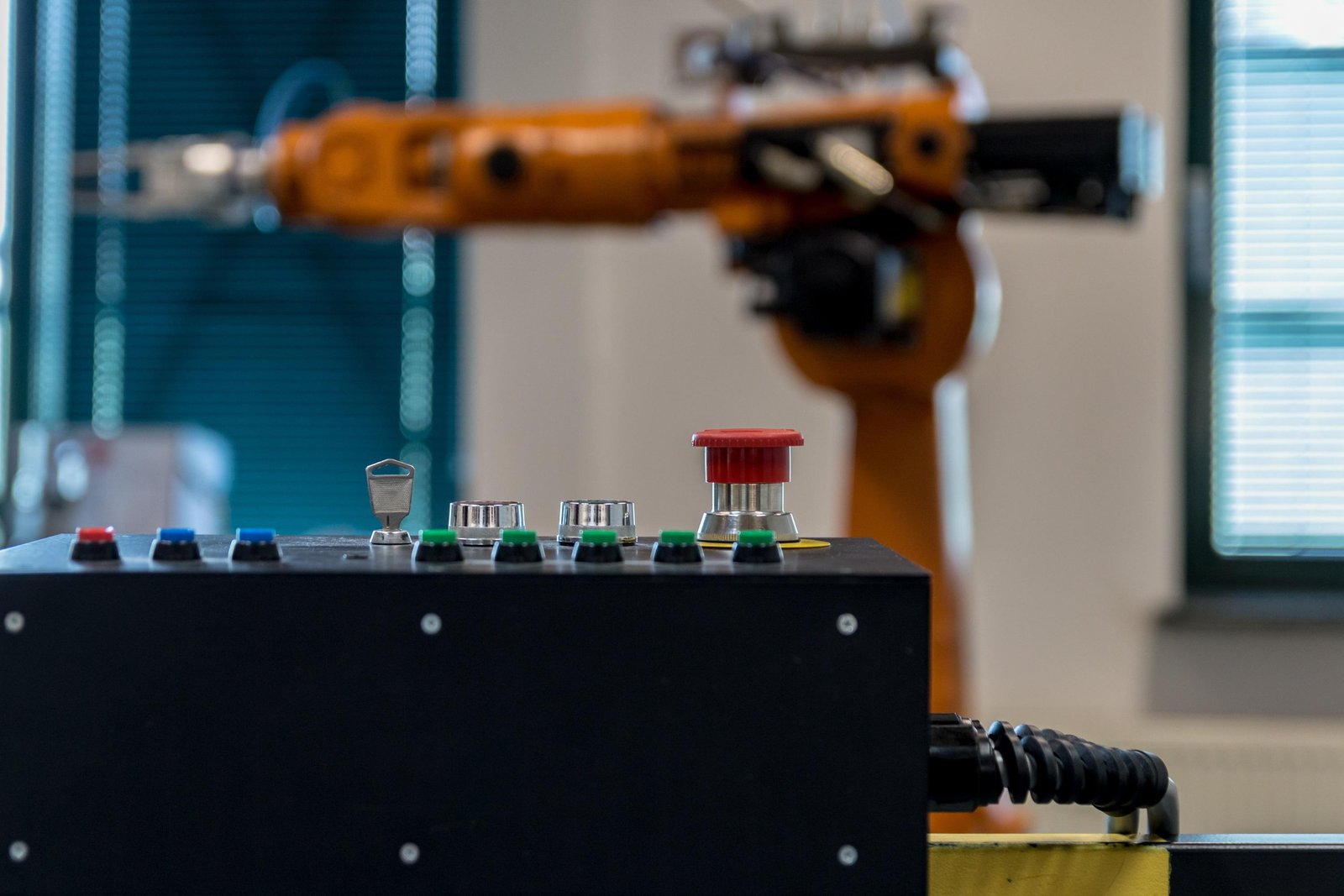

Engineered automation refers to the design and implementation of customized systems that perform tasks with minimal human intervention. These systems utilize state-of-the-art components such as robotics, software, sensors, and actuators to carry out repetitive or complex processes reliably. Unlike off-the-shelf solutions, engineered automation is tailored to meet specific operational needs, making it ideal for industries ranging from manufacturing to healthcare.

For example, in a production line, an automated system can inspect, assemble, and package products faster than a human workforce. It doesn't just increase speed but improves accuracy, ensuring fewer defects and higher overall quality.

The Benefits of Engineered Automation

Adopting engineered automation can deliver exceptional benefits that directly impact business success. Here's how it can transform operations:

1. Enhanced Efficiency

Automated systems can operate 24/7 without fatigue, drastically increasing productivity. They eliminate downtime caused by human limitations, allowing companies to meet demands even faster.

2. Improved Accuracy and Reliability

Manual processes often leave room for error. Engineered automation, on the other hand, ensures precise performance every time, reducing wastage and cutting costs related to inconsistencies.

3. Cost Savings

While the initial investment may seem significant, engineered automation often pays for itself in the long run. Lower labor costs, reduced waste, and increased production output lead to substantial financial savings over time.

4. Safety in Hazardous Environments

When tasks involve dangerous conditions, automation steps in to protect workers. For example, automated systems can handle exposure to chemicals, extreme temperatures, or physically strenuous processes, ensuring workplace safety.

5. Scalability and Customization

Engineered automation is adaptable to your specific needs. Whether you’re scaling up a production facility or refining small, intricate tasks, the flexibility of automation systems ensures seamless growth.

Applications of Engineered Automation

The versatility of engineered automation makes it suitable for numerous industries. Below are examples of where it’s revolutionizing workflows:

Manufacturing

From automobile assembly to electronics production, manufacturing is one of the top industries utilizing engineered automation. Complex tasks such as welding, machining, and material handling are now performed with remarkable speed and accuracy through robotics and automated machinery.

Healthcare

Medical industries rely on engineered automation to enhance precision and efficiency. For instance, automated systems are widely employed in medical device manufacturing, pharmaceutical packaging, and even surgical procedures.

Food and Beverage

Automation in the food and beverage industry ensures consistent quality and faster processing. Tasks such as sorting, packaging, and even quality inspections are carried out efficiently through automated systems.

Logistics and Warehousing

Automated solutions in logistics, such as smart conveyor systems and robotic arms in warehouses, optimize inventory management while reducing turnaround times.

Agriculture

Engineered automation is emerging in agriculture through robotic harvesters, drones for crop monitoring, and automated irrigation systems. These innovations help farmers improve yield while conserving resources.

The Future of Engineered Automation

The landscape for engineered automation is constantly evolving. With advancements in artificial intelligence (AI) and the Internet of Things (IoT), automation is set to become even smarter and more connected. Systems will soon be able to self-monitor, predict potential failures, and make autonomous decisions, reducing downtime and improving efficiency further.

Beyond industrial applications, automation technology is finding its way into everyday life, from smart homes to autonomous vehicles. This trend underscores its significance as a driver of innovation and societal progress.

Consider Partnering with Industry Experts

If you're eager to harness the benefits of engineered automation, working with experienced professionals can make all the difference. At Xtreme Automation LLC, we specialize in delivering tailored automation solutions designed to meet your unique needs. From concept to installation, our team provides expert guidance every step of the way.

How to Get Started

Adopting engineered automation starts with identifying your key operational challenges. Consider these steps to begin your automation journey:

- Assess Your Needs: Conduct an audit of your existing processes to find areas that could benefit from automation.

- Set Clear Goals: Define what you aim to achieve, whether it’s increased efficiency, cost reduction, or higher quality.

- Choose the Right Partner: Collaborate with experts like Xtreme Automation LLC to develop a customized system tailored to your goals.

Final Thoughts

Engineered automation is not just a trend; it is a necessity for businesses looking to stay competitive in a fast-paced world. Its ability to enhance efficiency, improve accuracy, and boost scalability ensures sustainable success for any industry. By exploring its benefits and working with experienced automation providers, you can stay ahead of the curve and unlock your business's full potential.

Don’t wait to revolutionize your operations. Get in touch with Xtreme Automation LLC today to bring smart, engineered solutions to your business!