The Polybutylene Succinate Production Cost is an essential factor for businesses and manufacturers involved in the production of biodegradable plastics, specifically polybutylene succinate (PBS). PBS is an eco-friendly, high-performance plastic used in various applications, including packaging, textiles, and automotive industries. As the world moves towards more sustainable materials, understanding the production cost of PBS becomes crucial for businesses to remain competitive and manage expenses effectively. This article explores the key factors influencing the Polybutylene Succinate Production Cost, including cost models, pre-feasibility studies, industrial trends, labor charges, utilities, logistics, and supply chain dynamics.

Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/polybutylene-succinate/request-sample

Understanding Polybutylene Succinate Production

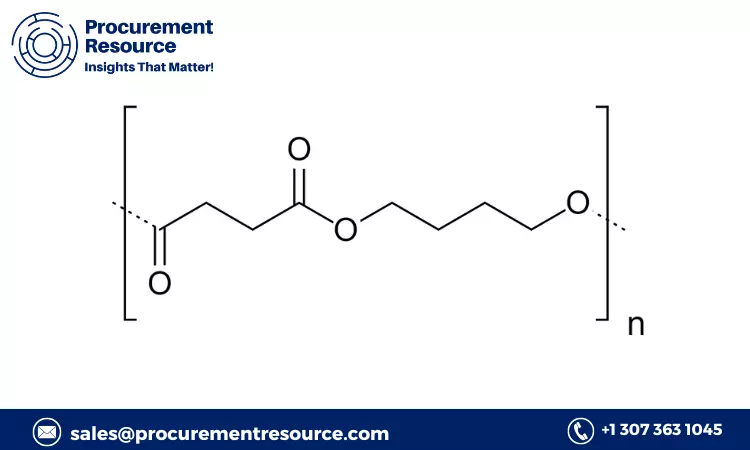

Polybutylene succinate (PBS) is a type of biodegradable polymer made from renewable resources. It is primarily used in biodegradable packaging, medical devices, and agricultural applications. The production of PBS involves several steps, including the synthesis of succinic acid, a key raw material, followed by polycondensation to produce the polymer. The cost of PBS production can vary depending on factors such as raw material prices, energy consumption, labor, and supply chain logistics. The growing demand for sustainable and environmentally friendly plastics has made PBS production more attractive for manufacturers looking to capitalise on the green materials trend.

Polybutylene Succinate Production Cost Report: Cost Model

A Polybutylene Succinate Production Cost Report provides a detailed analysis of all the factors that influence the cost structure of PBS manufacturing. The report typically includes an extensive breakdown of the cost model, which includes raw materials, energy, labor, and overhead costs. Each of these factors plays a crucial role in determining the overall cost of production.

Raw Materials

The primary raw materials used in PBS production are succinic acid and 1,4-butanediol (BDO). Succinic acid is typically derived from petroleum or renewable sources like corn and sugarcane. The cost of succinic acid can fluctuate based on factors such as market demand, raw material availability, and transportation costs. The price of BDO is influenced by the oil market and petrochemical industry dynamics, which can impact the production cost of PBS significantly. Thus, monitoring raw material prices is vital for manufacturers in controlling their production costs.

Energy Consumption

Energy costs are one of the largest contributors to the Polybutylene Succinate Production Cost. The process of synthesising PBS involves several energy-intensive steps, including high-temperature reactions and polymerisation processes. Depending on the production facility's location, energy costs can vary significantly. Companies that use renewable energy sources or implement energy-efficient technologies can reduce their production costs. As energy prices fluctuate, energy-efficient solutions become even more critical in managing the cost of PBS production.

Labor Charges

Labor costs can vary greatly depending on the location of the manufacturing plant, local wage levels, and the complexity of the production process. Skilled labor is required for the setup, operation, and maintenance of the production facility, which adds to the overall cost of production. Labour-intensive stages, such as quality control and R&D, also contribute to labor costs. Manufacturers looking to optimise labor charges can benefit from automation and streamlined operational processes.

Utilities and Overheads

In addition to energy and labor, other utilities such as water, waste treatment, and maintenance are key factors influencing the cost of production. The need for efficient waste management systems, especially in the production of biodegradable plastics like PBS, adds another layer of complexity to the production process. Utility costs can also be influenced by geographical factors and regulatory policies in different regions.

Industrial Trends Affecting Polybutylene Succinate Production Costs

The production cost of polybutylene succinate (PBS) is highly influenced by several industrial trends that shape the global market for biodegradable plastics. These trends include increased demand for sustainable packaging, regulatory pressures on plastic waste, and advancements in green technology.

Sustainable Packaging Demand

The rising demand for sustainable packaging solutions, driven by both consumers and businesses aiming to reduce their environmental impact, is one of the most significant trends impacting the PBS market. As governments and companies commit to reducing their carbon footprint, PBS is increasingly seen as a viable alternative to petroleum-based plastics. However, this demand has led to an increase in raw material prices and competition for supply, which can impact production costs.

Regulatory Pressures on Plastic Waste

With growing environmental concerns about plastic waste, regulatory pressures on plastic manufacturers have been tightening. Governments worldwide are introducing policies that promote the use of biodegradable materials like PBS, creating a strong market for these materials. While this regulatory shift is beneficial for the industry, it also creates challenges related to production scale-up, raw material sourcing, and compliance with sustainability standards.

Technological Advancements

Technological innovations in green chemistry and material science are playing a key role in reducing the production costs of PBS. For example, advancements in microbial fermentation methods for producing succinic acid from renewable sources have the potential to lower raw material costs. Furthermore, new catalysts and more efficient polymerisation methods are being developed to make PBS production more cost-effective. These innovations are driving cost reductions while improving the environmental profile of PBS.

Logistics and Supply Chain Factors Influencing Production Cost

The cost of logistics and the supply chain is another crucial element of the Polybutylene Succinate Production Cost. Shipping raw materials, storing chemicals, and delivering finished products to customers are all integral parts of the PBS production process. Supply chain disruptions, whether due to geopolitical issues, natural disasters, or changes in trade policies, can lead to higher transportation and storage costs. Optimising the supply chain by using local suppliers, reducing transportation distances, and implementing just-in-time inventory systems can help lower logistics costs.

In addition, the ongoing global challenges with transportation, such as container shortages and rising freight costs, have added upward pressure to the overall cost of production for manufacturers relying on international supply chains.

Request for the Real-Time Prices

For businesses seeking accurate and up-to-date cost data, accessing real-time prices is essential for making informed decisions in a fast-paced market environment. Understanding the fluctuations in raw material prices, energy costs, and logistics expenses is crucial to adapting procurement strategies and maintaining profitability.

For more detailed information or to request Free Sample - https://www.procurementresource.com/production-cost-report-store/polybutylene-succinate/request-sample

Procurement Resource for Polybutylene Succinate Production

Effective procurement is essential for controlling production costs in polybutylene succinate manufacturing. By sourcing high-quality, cost-effective raw materials and establishing reliable supply chains, companies can minimise operational risks and improve their bottom line. As a business looking to optimise PBS production costs, it is important to stay informed about the latest market trends, supplier options, and logistical considerations.

Procurement professionals can benefit from collaborating with suppliers that provide competitive pricing, transparent lead times, and flexible contract terms. Additionally, adopting a long-term relationship with key suppliers can help mitigate price volatility in the raw material markets.

By understanding the intricacies of the Polybutylene Succinate Production Cost, businesses can take strategic steps to optimise their operations, control costs, and position themselves for success in the growing market for sustainable plastics.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA